Installing

a 1.8lt MX5 differential into a <94 1.6lt

Why?

The 1.6

differential is a known weak spot in the drivetrain.

Hard driven cars with no mods can grenade these diffs and cars with power mods will

certainly be capable of this! Within 4 weeks of buying my Roadster my first

diff went (due to oil starvation from a cracked case) and 6 years on, my 2nd

one gave up the ghost and this was accelerating in a straight line. So, to

avoid this problem again I decided to upgrade to the 7 inch ring gear which is

in the 1.8lt differential. This is a larger unit and is fairly rugged. In the pic below you can see 1.8lt unit on the right.

It is both

longer and wider so you will also have to change the halfshafts

and driveshaft to 1.8lt units.

Procedure :

First, buy

your parts.

1) 1x 1.8lt

differential (this project sourced it from www.traynors.co.uk

, good service!)

2) 2x 1.8lt

Halfshafts (same source as 1, if you have ABS, make

sure they come from an ABS car as it’ll need the grooved end for the sensor,

see pic)

3) 1x 1.8lt

driveshaft (same source as 1, see pic for differing

lengths, lower one is from the 1.8lt car)

4) 2x hubnuts (Mazda)

5) 2x

differential output shaft oil seals (Mazda)

6) 2x halfshafts C-clips (Mazda)

7)

Differential oil & Gearbox oil (I went for the Redline brand from www.FlyinMiata.com)

8) Exhaust

gasket.

Now, give yourself

a couple of days to do this and try and have someone help as it’s a pig of a

job on your own (believe me… I KNOW!).

1) Night

before, WD-40 every nut you think you’ll have to remove (bar the driveshaft and

halfshaft nuts at the diff as they’re not very

tight).

2) Put the

car in gear and put the handbrake on.

3)Bang

out the staking on the hub nuts (the bit that’s bent inward to stop it coming

off) with a dot punch + hammer. Get a LONG breaker bar to put over your

ratchet’s handle (29mm socket required BTW!) and pull! If the car moves, get

someone to put their foot on the brake. Mine were REALLY tight and needed an

airgun used to remove tractor wheels to loosen them (friendly local mechanics

come in handy here).

4)Loosen

wheel nuts.

5)Put the

car on axle stands under the jacking points on the sills.

6)Remove

wheels.

7)Remove

Brake calipers (a good time to think about changing

the pads and greasing the slider pin!) and ABS sensor (if fitted) and tie out

of the way with cable ties. Remove hubnuts.

8)Remove

the exhaust’s backbox (or from the cat back if you

can to give more room).

9)Remove

brace between lower wishbones.

10)Unbolt halfshafts from the diff’s output hubshaft flanges

(12mm)

11)Unbolt the

driveshaft from the diff (you’ll have to take the car out of gear to move the

shaft round half a turn to get to the other nuts, then put it back in gear so

you can turn against the nuts)

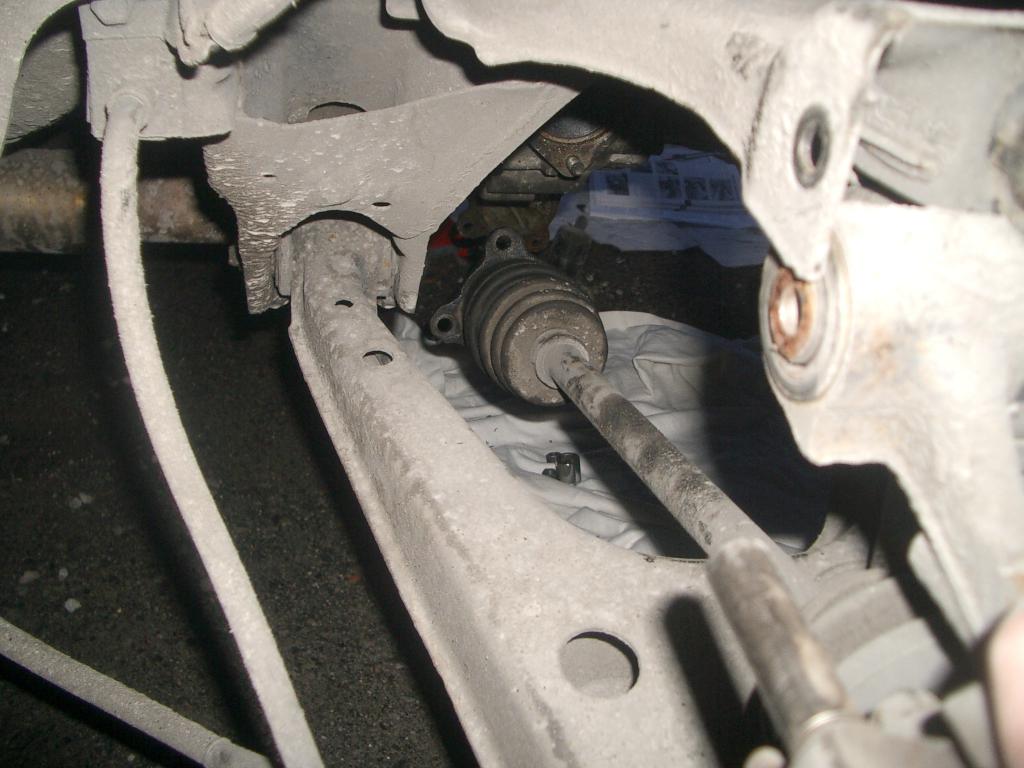

12)Pull the halfshafts out of the

hubs, if they’re stuck, get a lump hammer and give them a couple of whacks,

they WILL come out so be persistant. (ignore the hammer in the pic ;-) )

13)Put a trolley jack under the diff and jack it up so that

it’s just touching the bottom.

14)Unbolt the 2x17mm bolts that hold the Power Plant Frame to

the Diff.

15)One of these bolts had a “collar” on it, in the base of the

collar (bit nearest the PPF) there are 2 grooves in which you can insert the

tip of a screwdriver to lever it out of the PPF.

Be careful

from here on, try not to pull the PPF downwards too much as you don’t want to

damage the firewall nor the gearbox (where the other end of the PPF is bolted)

16)Remove the 2x12mm bolts on each side of the diff carrier’s

arms, then loosen the 2x17mm bolts, be careful not to drop the diff on your

head! This is where having someone with you can be handy ;-)

17)It will be still attached to the PPF by a collar on the

upper part of the PPF so with this in mind, try and lever out the bottom of the

diff from the PPF and unbolt the 12mm bolts holding the spacer between the diff

and the PPF, then carefully remove the diff while lowering the jack, it takes a

bit of fiddling to get it out. Again.. the diff is heavy, so keep the jack under it as much as

possible.

18) Drain

the gearbox oil

19) Drain

the old oil from the 1.8lt diff (you’ll need a 23mm diff for the fill hole and

a 24mm for the drain hole)

20)

Pull/slide the driveshaft out of the gearbox

21) Put in

the new driveshaft (it’ll just slide into the rear of the gearbox)

22) Now you

need to take the stub shafts out of the new diff as they won’t be needed with

the one piece halfshafts you should have received.

This is easily accomplished by using a couple of levers to pry them out of the

diff.

23) Renew

the oil seals in the space from where the stub shafts were removed. (below is a view thru the diff)

24) Put the

new diff on a trolley jack and roll it in under the car. Jack it up and tilt it

back so that it slots back into the PPF (again, this can be fiddly, trick is to

try and get the top in first, then the bottom while lining up the carrier arms

17mm bolts) Be careful not to let it fall off the jack!

25) Screw

on the 17mm bolts to hold the diff in place, then

replace the 2x12mm bolts. And tighten.

26) Replace

the 2 long 17mm bolts not forgetting to replace the collar that was levered out

earlier.

27) Bolt on

the driveshaft to the diff (you can reuse your 1.6lt bolts + nuts here) using

the same method of taking the car out of gear and moving the driveshaft as you

did earlier.

28) Unbolt the upright from the control arm so that you can pull

it back from the car

29) Fit

your new c-clips to the diff ends of your halfshafts

being sure to line the “open” bit of the clip so that it’s facing upward before

inserting into the diff. Tap it fully in using a rubber mallet on the end of

the halfshaft. Try pulling it back out to ensure it

is seated properly.

30) Pull

back the upright and insert the (now copper greased) splined

end into the hub.

31) Bolt

the upright back onto the control arm (you may need to jack it up a bit to get

the bolt holes lined up again)

32) Replace

the ABS sensor and brake calipers (don’t forget the

copper grease on that sliding pin!).

33) Bolt

the rear suspension brace back on.

34) Refill the

gearbox oil and differential oil (upper most bolt is the fill hole!)

35) Admire

your work ;-)

36) Fit new

exhaust gasket if required (mine was a slip-fit) and replace backbox.

Job done!

Disclaimer

This product is meant for educational purposes only. Any

resemblance to real persons, living or dead is purely coincidental. Void where

prohibited. Some assembly required. List each check

separately by bank number. Batteries not included. Contents may settle

during shipment. Use only as directed. No other warranty expressed or implied.

Do not use while operating a motor vehicle or heavy equipment. Postage will be

paid by addressee. Subject to approval. This is not an

offer to sell securities. Apply only to affected area. May be

too intense for some viewers. Do not stamp. Use other side for

additional listings. For recreational use only. Do not

disturb. All models over 18 years of age. If condition persists, consult your

physician. No user-serviceable parts inside. Freshest if

eaten before date on carton. Subject to change without

notice. Times approximate. Simulated picture.

No postage necessary if mailed in the